Denver Water’s Gross Reservoir Dam Expansion Project will nearly triple the reservoir’s water-storage capacity. Low-carbon roller-compacted concrete (RCC) will be used to increase the dam’s height by 131 ft., its length by 890 ft., and its thickness by up to 90 ft. Upon its completion in 2027, the project will provide one-quarter of Colorado’s population (1.5 million people) with greater water security during droughts and deliver essential resiliency in the face of increasing climate-change impacts.

THE CHALLENGE

- Reducing carbon footprint of construction, a high priority for project stakeholders.

- Constructing the foundation initially called for an estimated 15,000 tons of Type I/II Ordinary Portland Cement (OPC) for producing 68,000 CY of high-performance concrete.

- Building 118 steps to raise the dam’s height from 340 ft. to 471 ft. initially called for approximately 60,000 tons of Type I/II OPC for producing 740,000 CY of RCC in batch plant on jobsite.

- The remote mountainous work area—150 miles from the cement plant and with limited onsite storage capacity—created logistical challenges for continuous supply of large product volumes.

THE SOLUTION

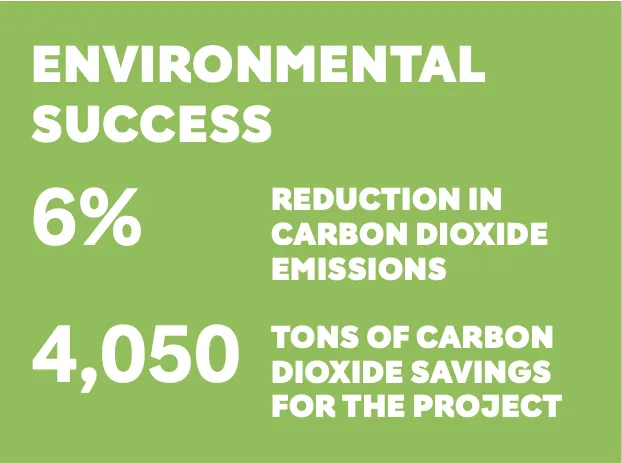

- Switching from Type I/II OPC to Type IL Portland Limestone Cement (PLC) will reduce the concrete dam’s embodied carbon by 6% while achieving the project’s stringent performance requirements.

- Estimated 75,000 tons of low-carbon OneCem® PLC used in 800,000+ CY of concrete for the project will provide CO2 savings of 4,050 tons when compared to OPC.

- Extensive production forecasting, logistics planning and coordination with project partners will ensure reliable, on-demand product deliveries to keep construction schedules on track 24/7.

Photos and videos courtesy of Denver Water.

OneCem® Portland Limestone Cement

OneCem provides everything you expect and need from cement - strength, durability, performance and workability - while also delivering a reduced carbon footprint. OneCem creates less CO2 than traditional Portland cement.