The world needs to build the equivalent of New York City every month for the next 40 years to keep pace with population growth. At that rate of construction, we simply cannot achieve our climate imperatives without changing our operations, approach to manufacturing and the methods and materials we use to build.

An industry-wide commitment to lowering the carbon footprint of the built environment must drive and enable all sectors of the building and construction process to act quickly to decarbonize by mid-century. As a leader in the US market, Holcim believes it’s possible to Decarbonize Without Compromise. We’re relentless in our pursuit of a full range of decarbonization solutions for our customers and operations.

Advancing Sustainable Construction: Specifying Low-Carbon Concrete

Holcim’s innovative low-carbon concrete and cement materials are vital solutions for global warming and extreme climate change. Specifying these materials will greatly aid in creating a more sustainable built environment amidst increasing demand.

Watch Video

Concrete CO2 Saver

Compare CO2 savings between ECOPact and conventional concrete and learn the equivalents for your Total Carbon Reduction Potential.

Resources by Role

Architect

Discover how our low-carbon building materials create new opportunities to push the boundaries of sustainable architecture.

Owner

Help shape the future of the built environment with low-carbon solutions that have a positive impact on the communities we live and build in.

No compromise on durability

The strengths of our products strengthen your efforts to decarbonize.

Holcim low-carbon ECOPlanet cements and ECOPact concrete deliver 100% performance while ensuring a minimum of 30% reduction in carbon.

- All ECOPlanet cements and ECOPact concretes are tested and certified to key standards like ACI 318.

- ECOPlanet cements and ECOPact concretes routinely improve concrete durability in many applications.

No compromise on flexibility

Performance you can count on, no matter what you’re working on.

From the building of infrastructure, commercial structures or residential projects – to paving, high-rises or precast architectural applications – ECOPlanet and ECOPact products provide sustainable solutions.

- ECOPact concrete mixes place, pump and finish just like conventional concrete.

- Stringent quality controls ensure ECOPlanet can handle even the most demanding infrastructure applications, like highways and bridges.

No compromise on ambition

Low-carbon construction at scale.

No matter how large the project, our range of low-carbon solutions can deliver CO2 reduction goals for your next project.

- Holcim is making low-carbon cement the standard by shifting all of our US plants to produce low-carbon cements exclusively. This transition translated into approximately 1.5 million tons of CO2 saved in 2023.

- Holcim's wide range of expertise allows us to deliver low-carbon solutions tailored to your specifications.

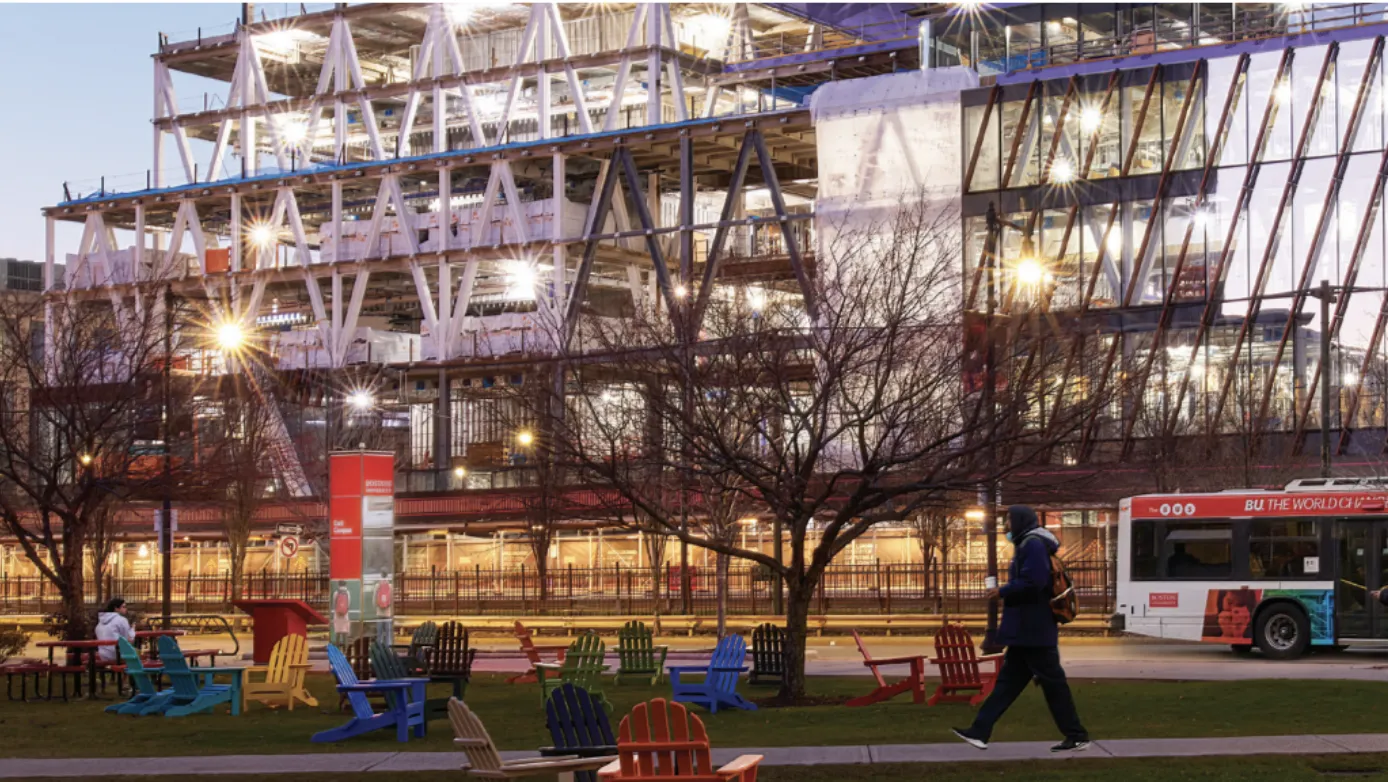

No compromise on vision

Change how you build, not what you build.

Building low-carbon doesn’t mean limiting your creativity. Our project partner teams have the expertise and tools to help you understand how your most original designs and design features can be realized with low-carbon building materials.

No compromise on progress

Expanding critical infrastructure while reducing its CO2 footprint.

As governments invest in infrastructure to mitigate climate change impacts, our innovative materials are helping reduce the carbon embodied in their construction.

Our team of experts will help you solve the most difficult logistical challenges to ensure a continuous supply of large volume low-carbon building materials.

Low-Carbon Building SolutionS

Holcim offers a suite of low-carbon products that enable US customers to decarbonize in ready-mix concrete without compromising on performance.

Reduces embodied carbon in construction by at least 30% with equal or better properties than conventional concrete. Available in a wide variety of strength classes and compliant with industry standards.

Delivers at least 30% lower carbon footprint with equal or superior performance than Type 1L, helping to lower energy consumption and greenhouse gas emissions.

Recycle concrete demolition materials into aggregate for use in new building solutions with no compromise on performance, while reducing the amount of concrete sent to landfills and our dependency on raw materials.