What is ECOPact | Why ECOPact? | Benefits | How ECOPact is Made | Case Studies

Today, taking steps to advance a climate-neutral existence is no longer an option in the construction industry. With nearly 40 percent of our world’s CO2 emissions linked to the way we build and operate buildings—and 30 percent of this footprint happening at the building phase—our industry has a responsibility to implement solutions that can make the significant impact required to help bring us out of a global environmental crisis.

With the vision of leading the way to net-zero construction, Holcim developed ECOPact low-carbon concrete, combining innovative design with extensive research and development. Offering the industry’s broadest range of low-carbon concrete products, ECOPact delivers the low-carbon concrete solution our world needs, without compromising on the performance our industry demand.

Concrete CO2 Saver

Compare CO2 savings between ECOPact and conventional concrete and learn the equivalents for your Total Carbon Reduction Potential.

What is ECOPact?

- ECOPact is a concrete with lower embodied carbon content compared to a reference concrete designed with OPC.

- Demonstrates equal or better properties than conventional concrete.

- Offers assurance of quality and genuine lowering of the environmental impact.

How is ECOPact made?

- ECOPact is a concrete solution of innovative design combined with extensive research and development.

- It contains an innovative mix of supplementary cementitious materials and admixtures technology.

- ECOPact is produced locally, recyclable and supports a circular economy.

- Where allowed, ECOPact can include construction and demolition waste enhancing its environmental benefits by further saving natural resources.

Why should you buy ECOPact?

- Because it is essential to ACT NOW, to preserve what we have and to build a better future.

- To be positioned as an industry partner with a vision for a better future.

- To become an active contributor to the conservation of the global environment.

Why is ECOPact a "green" concrete?

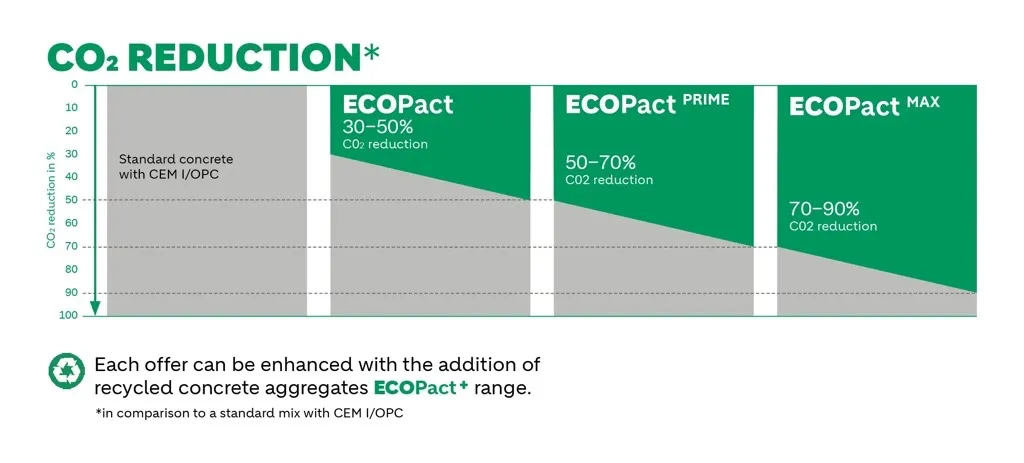

- It reduces the carbon footprint of concrete by at least 30%.

- It contributes to a circular economy by closing material cycles.

- Enhances resource conservation.

How the Concrete Industry is Going Green with ECOPact

Read how performance standards and government initiatives are helping push the industry toward greener concrete options.

WHY ECOPACT?

Decarbonizing the built environment is essential for a net-zero future. Almost 40% of our world’s CO2 emissions are linked to the way we build and operate buildings. 30% of this footprint happens at the building phase.

ECOPact is a low-carbon concrete product range which can reduce the embodied carbon of buildings, infrastructure and homes by at least 30% without offsets.

With ECOPact, you can:

Easily reduce the environmental impact of your project with no compromise in performance

Achieve an embodied carbon reduction of at least 30% without the use of offsets

Contribute to a circular economy by diverting waste from landfill and closing material cycles

Get green building certifications

Maintain product strength and quality

Have a wide range of mixes available for different strengths and applications

Place, pump and finish like conventional concrete

Want to learn more about ECOPact?

100% PERFORMANCE

ECOPact has equal or better properties than conventional concrete.

It is available in a wide variety of strength classes and is compliant with industry standards.

HOW IS IT MADE?

ECOPact is a concrete solution of innovative design combined with extensive research and development.

It contains an innovative mix of supplementary cementitious materials and admixtures technology.

ECOPact is produced locally, recyclable and supports a circular economy.

Where allowed, ECOPact can include construction and demolition waste enhancing its environmental benefits by further saving natural resources.

EASY APPLICATIONS

ECOPact mix designs can be used in a variety of structural components: from foundations, columns and beams, to walls, driveways and walkways.

It can be easily handled, pumped and finished like conventional concrete.